The Three Types Of Manufacturing Costs In A Job Order Costing System Include

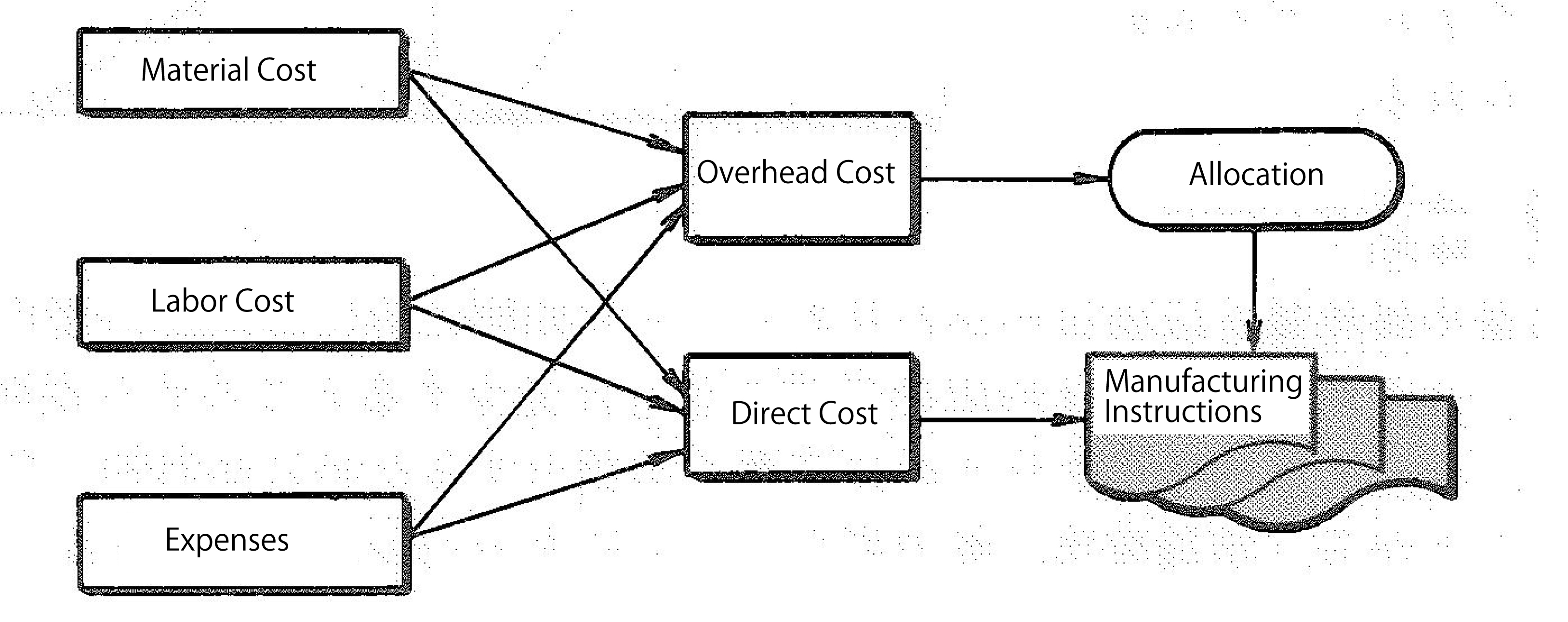

The three types of manufacturing costs in a job order costing system include. It is very easy. Here there is a form to fill. C This is actual manufacturing overhead for the period and includes indirect materials indirect labor factory rent factory utilities and other factory-related.

The information needed include. MRP suites may also include a module for configure-price-quote CPQ functionality typically used by sales teams to provide quick and accurate custom quotes for built-to-order operations. In traditional costing system overhead costs are assumed to be influenced by only units produced.

Here are the five most common types of manufacturing inventory. Weighted Average Costs This is done by dividing the cost of goods that are available for sale by the number of products that are available for. Product costs are related to goods produced or purchased for resale and are initially identifiable as part of inventory.

If we include a yield of 80 in the product costing we need to include the output weight 400g as the input quantity in the costing. Job Costing system preferences. Once payment has been made in full your order will be assigned to the.

Click on the order now tab. The information needed include. 6 Conversion costs include _____.

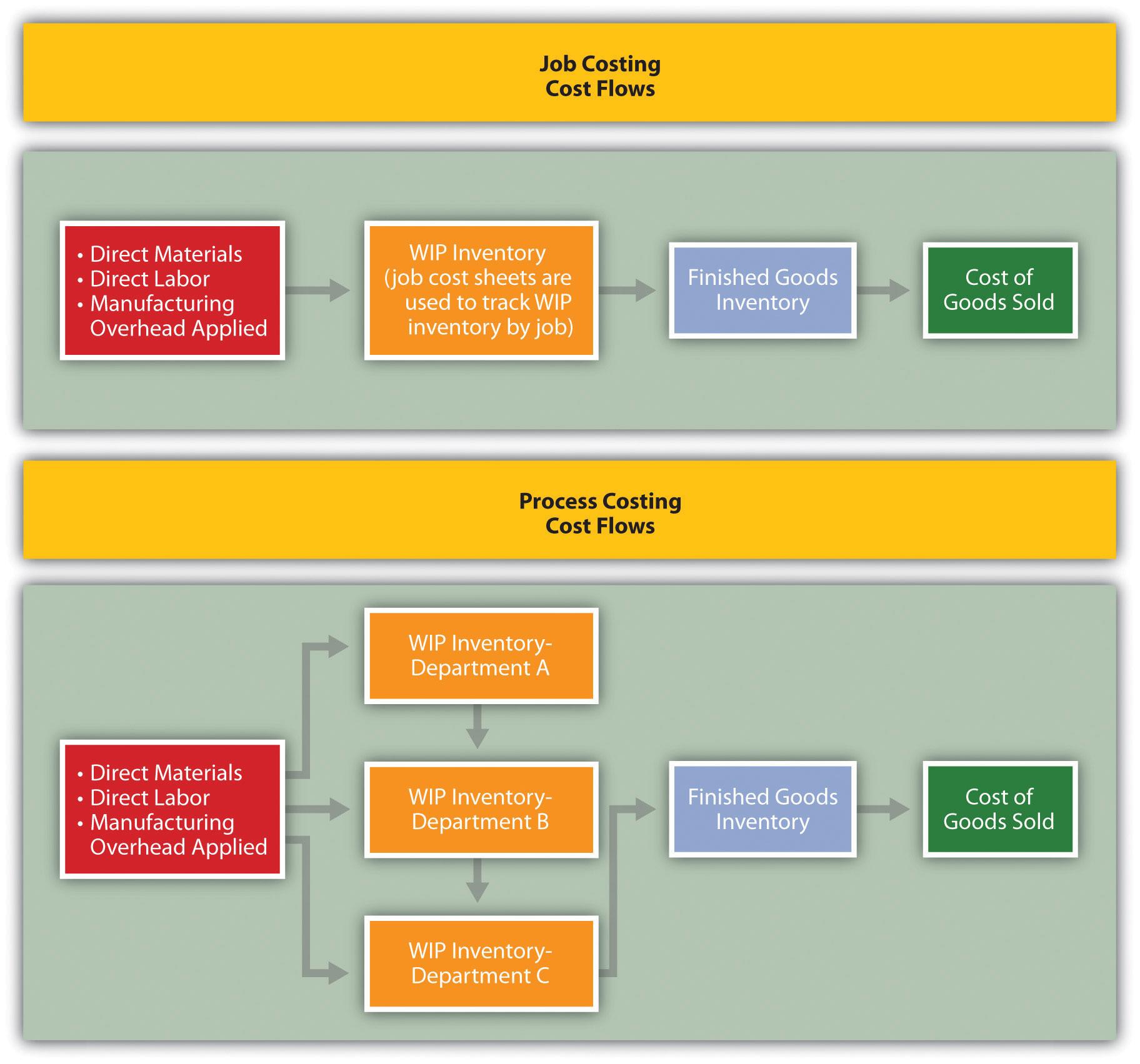

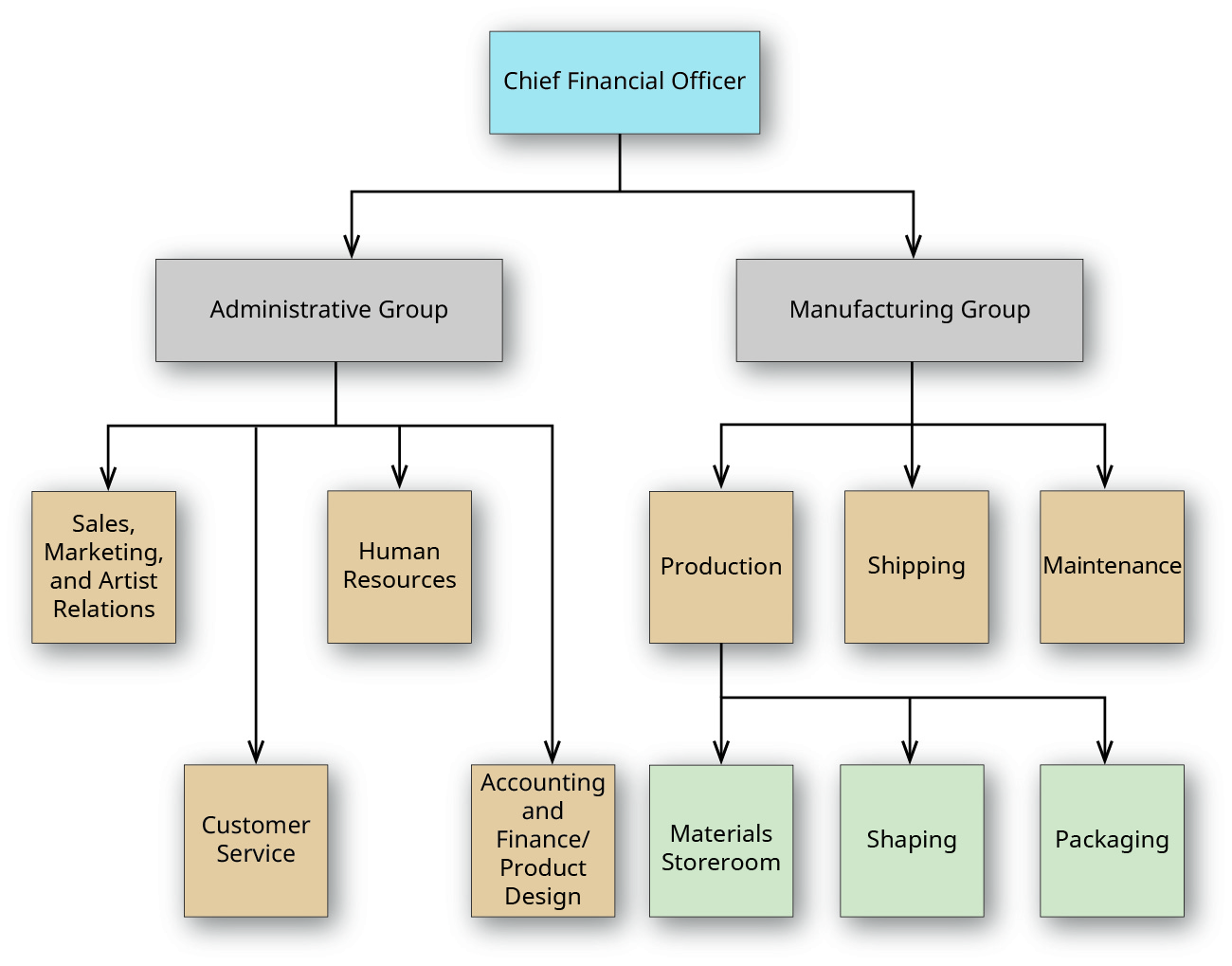

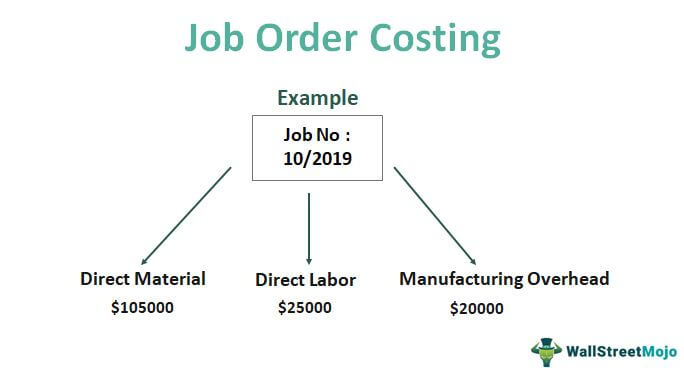

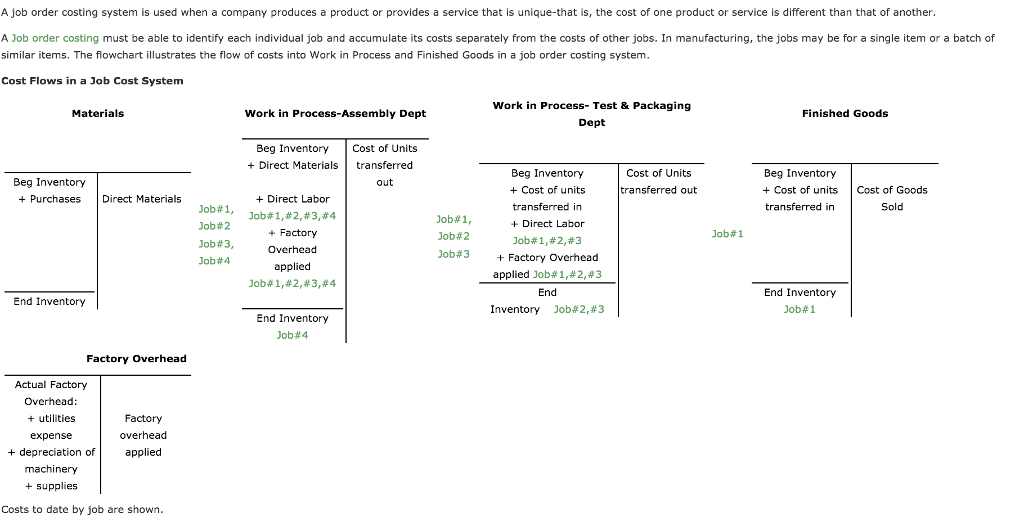

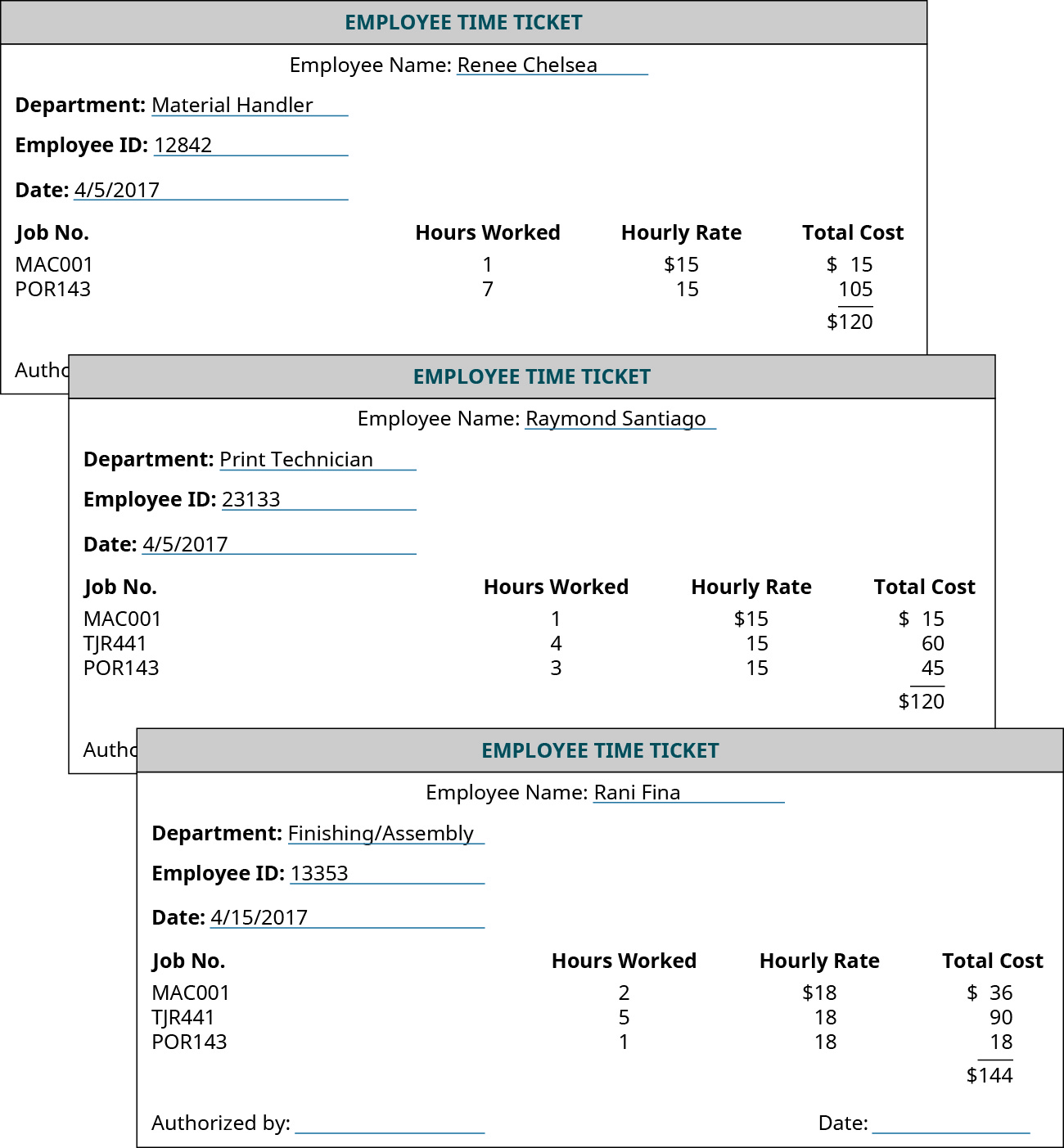

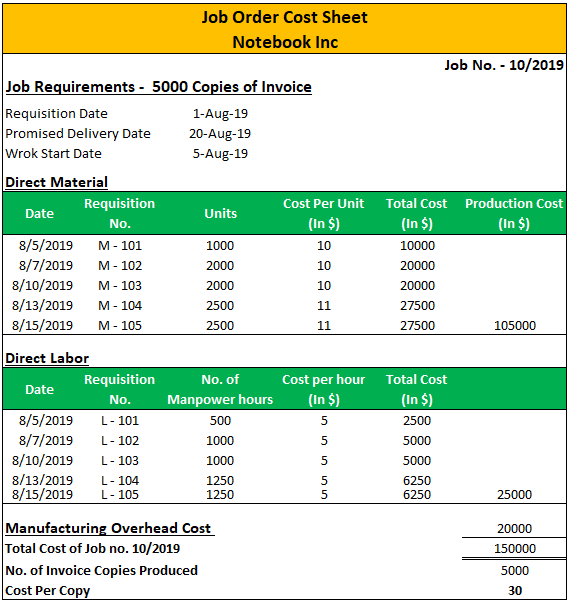

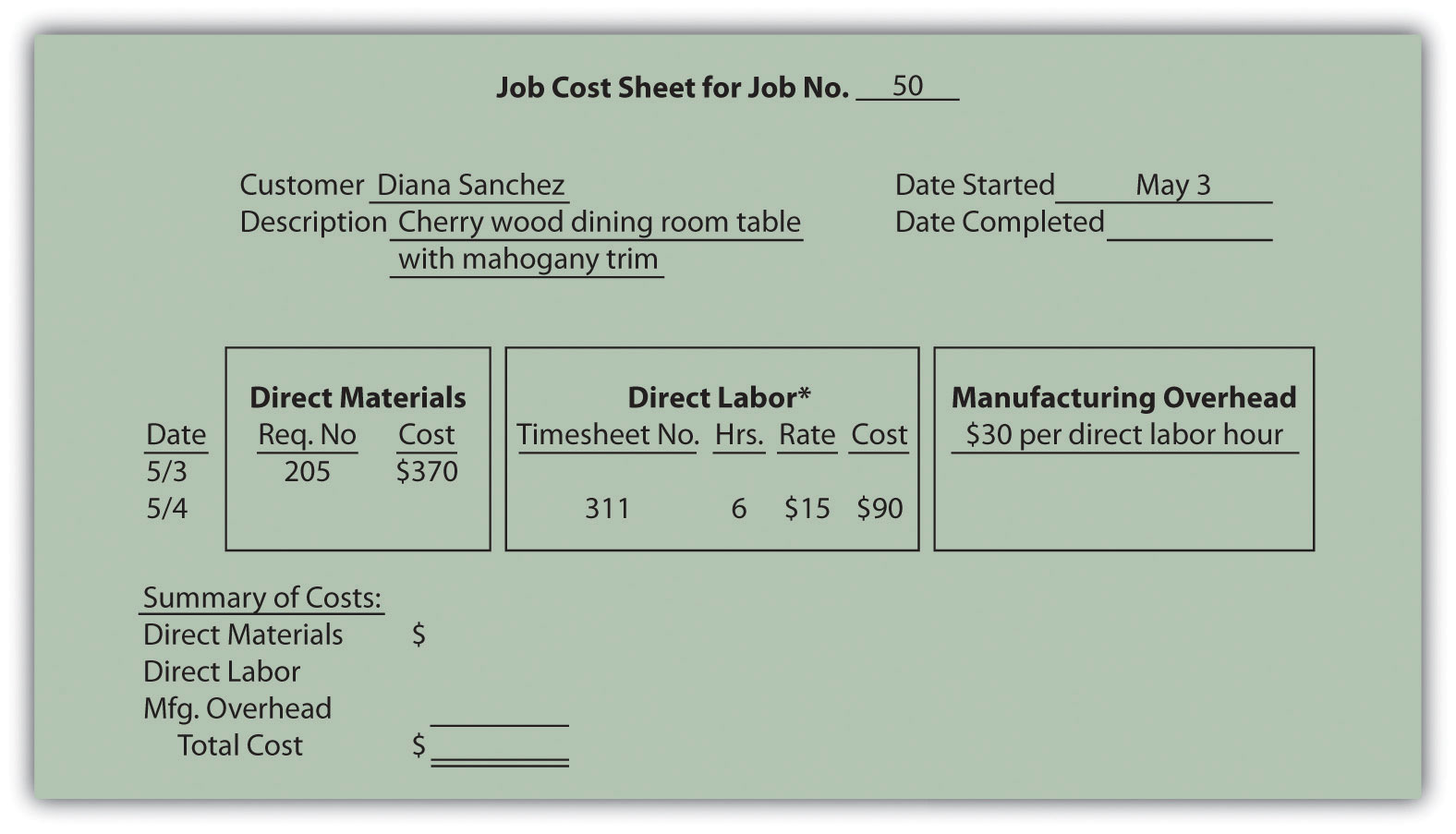

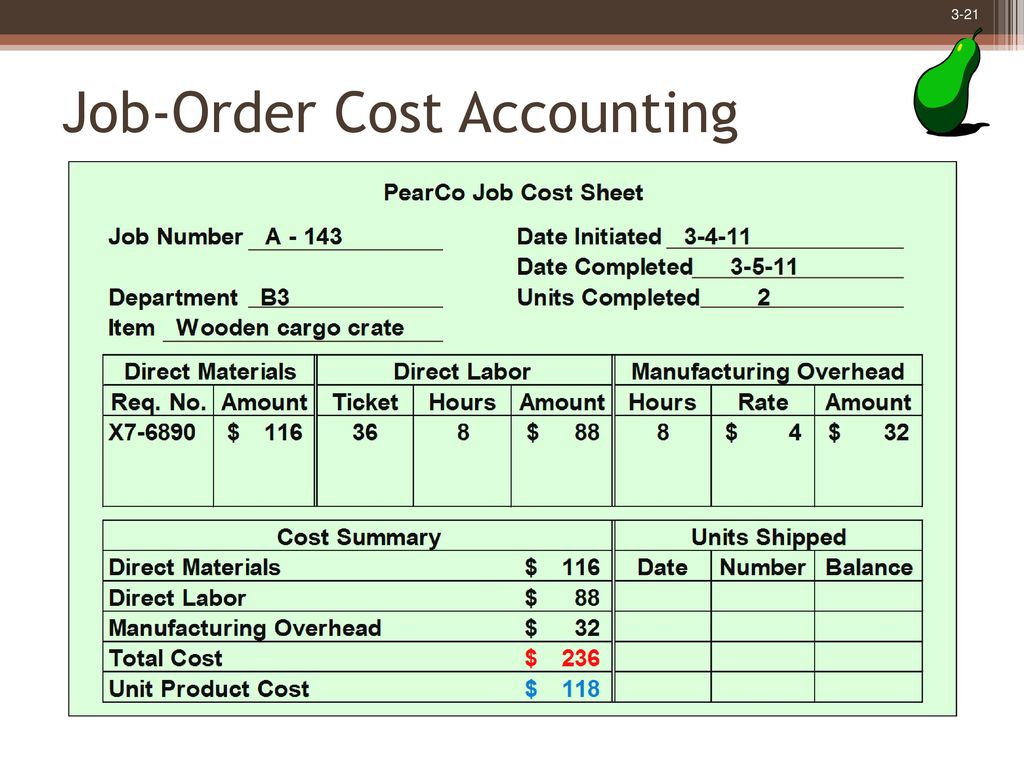

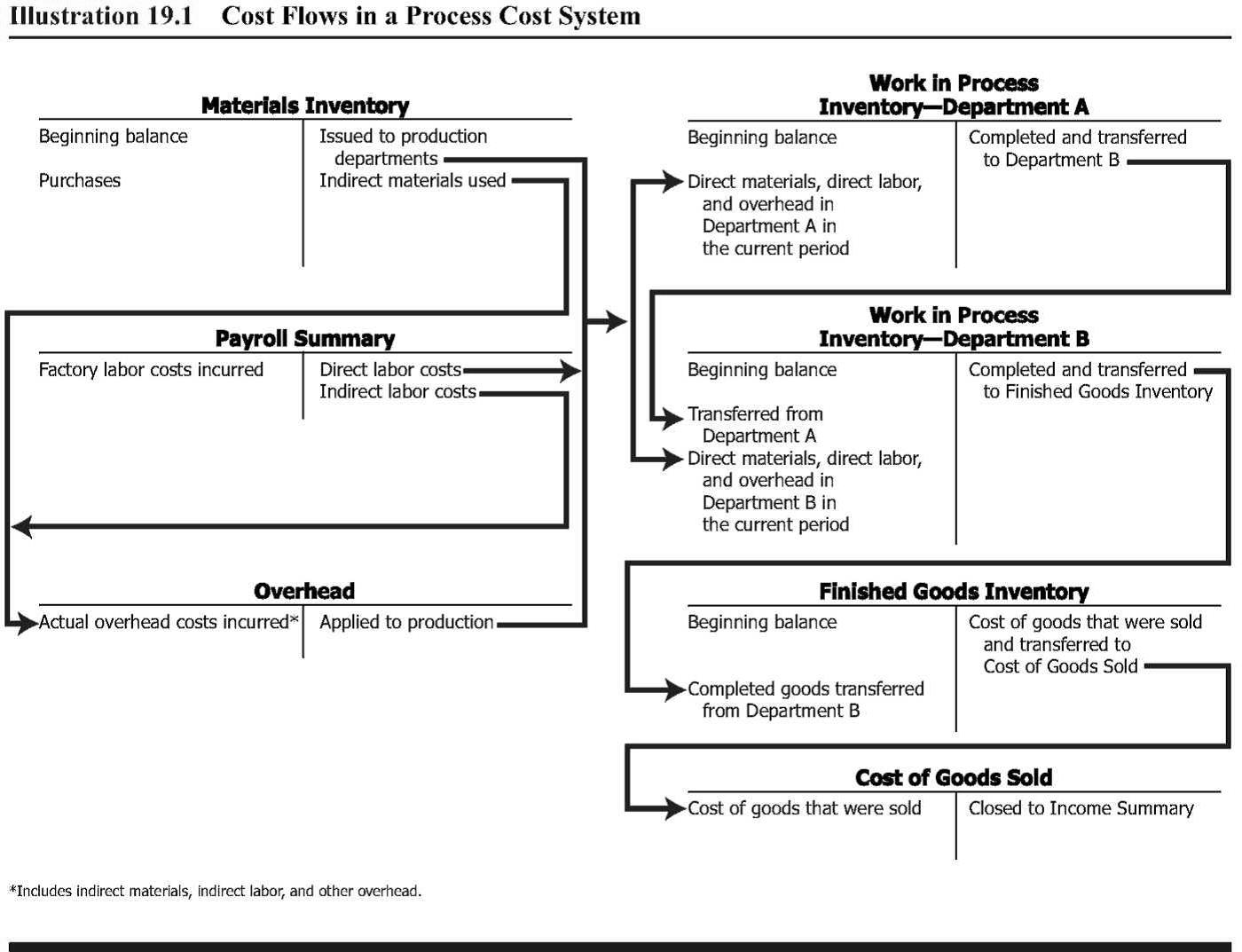

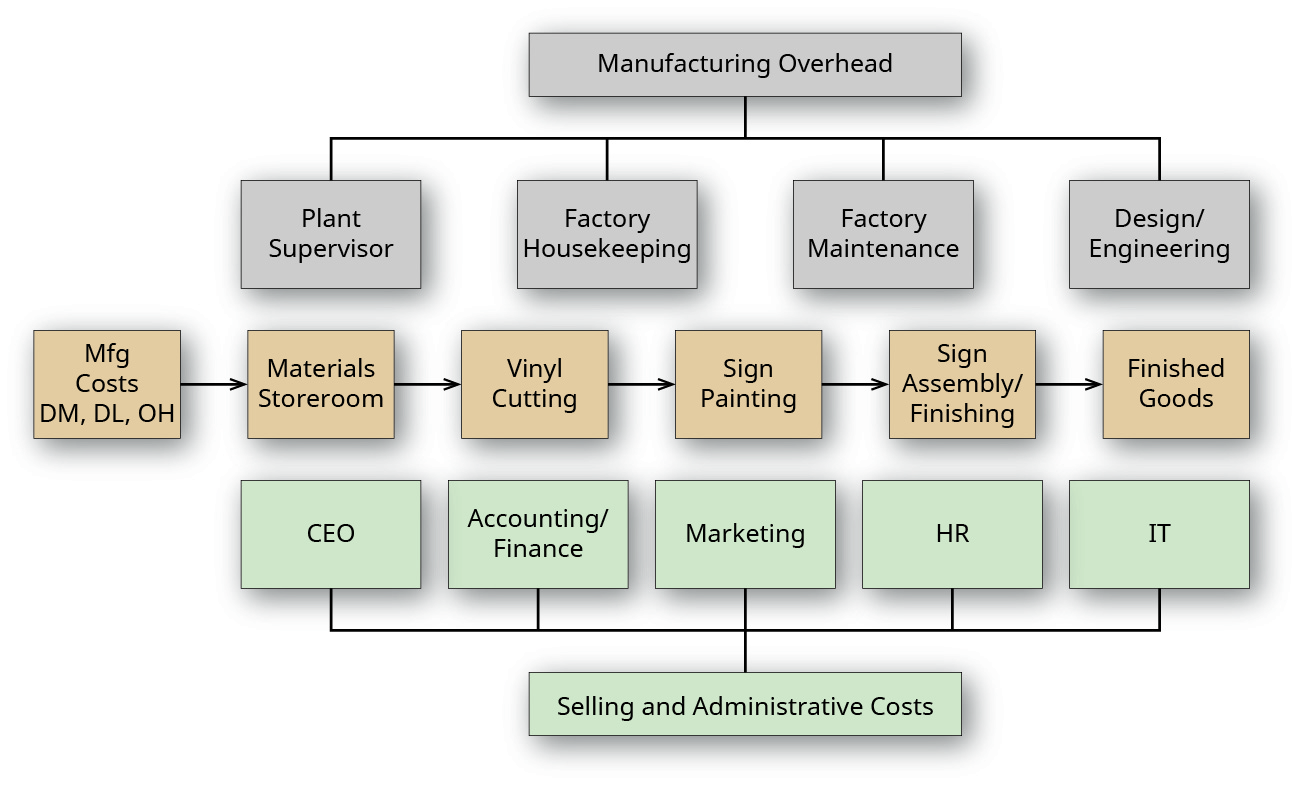

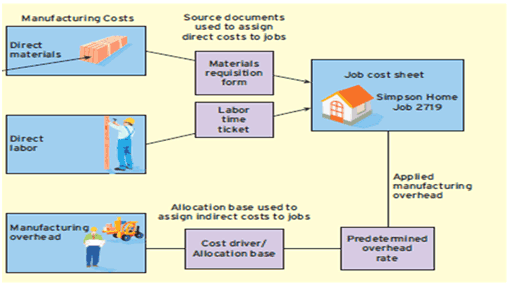

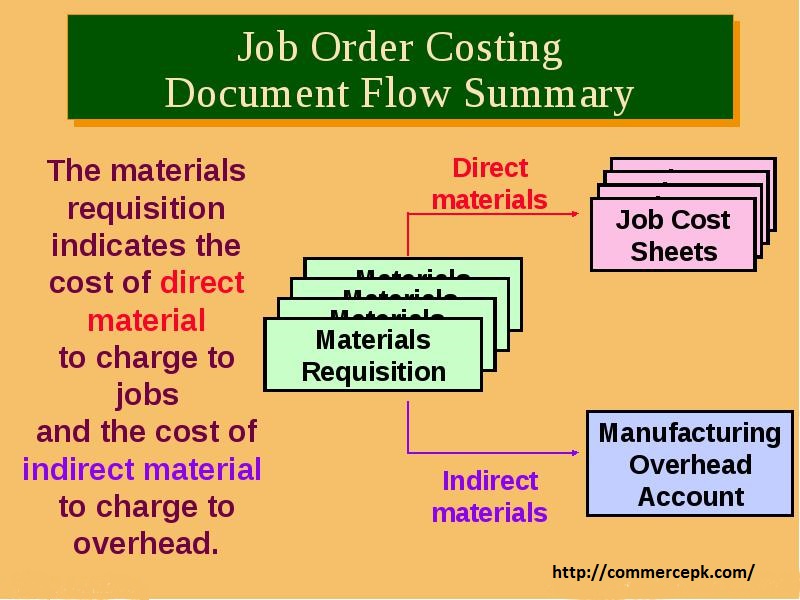

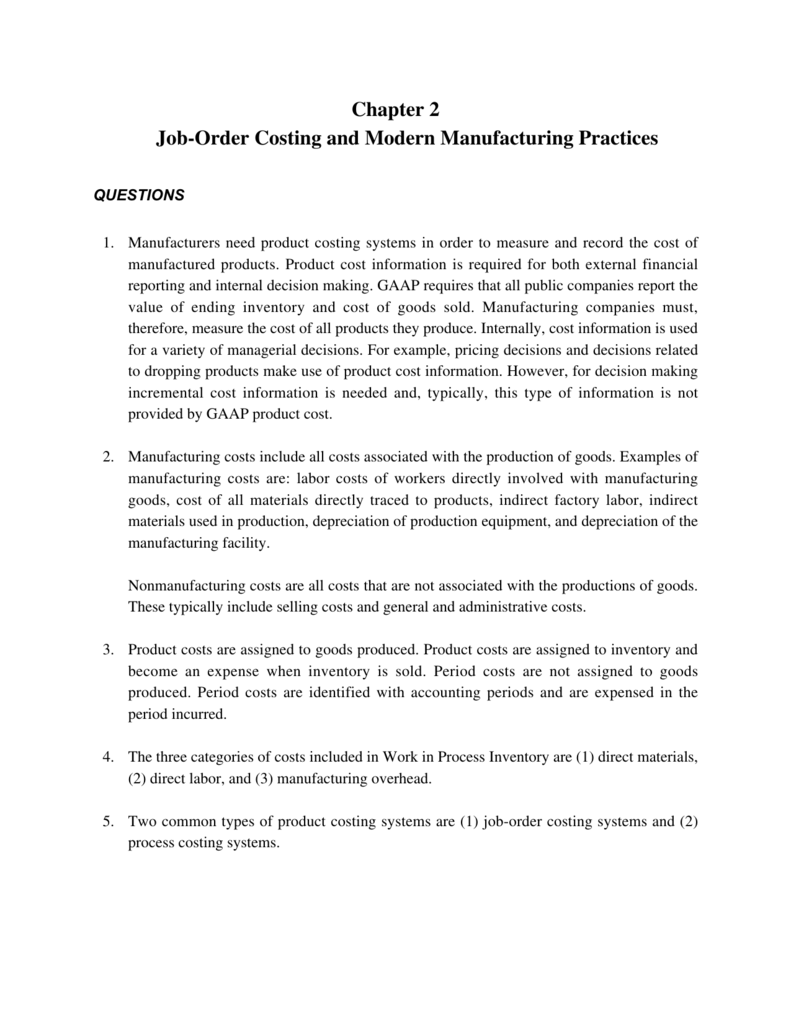

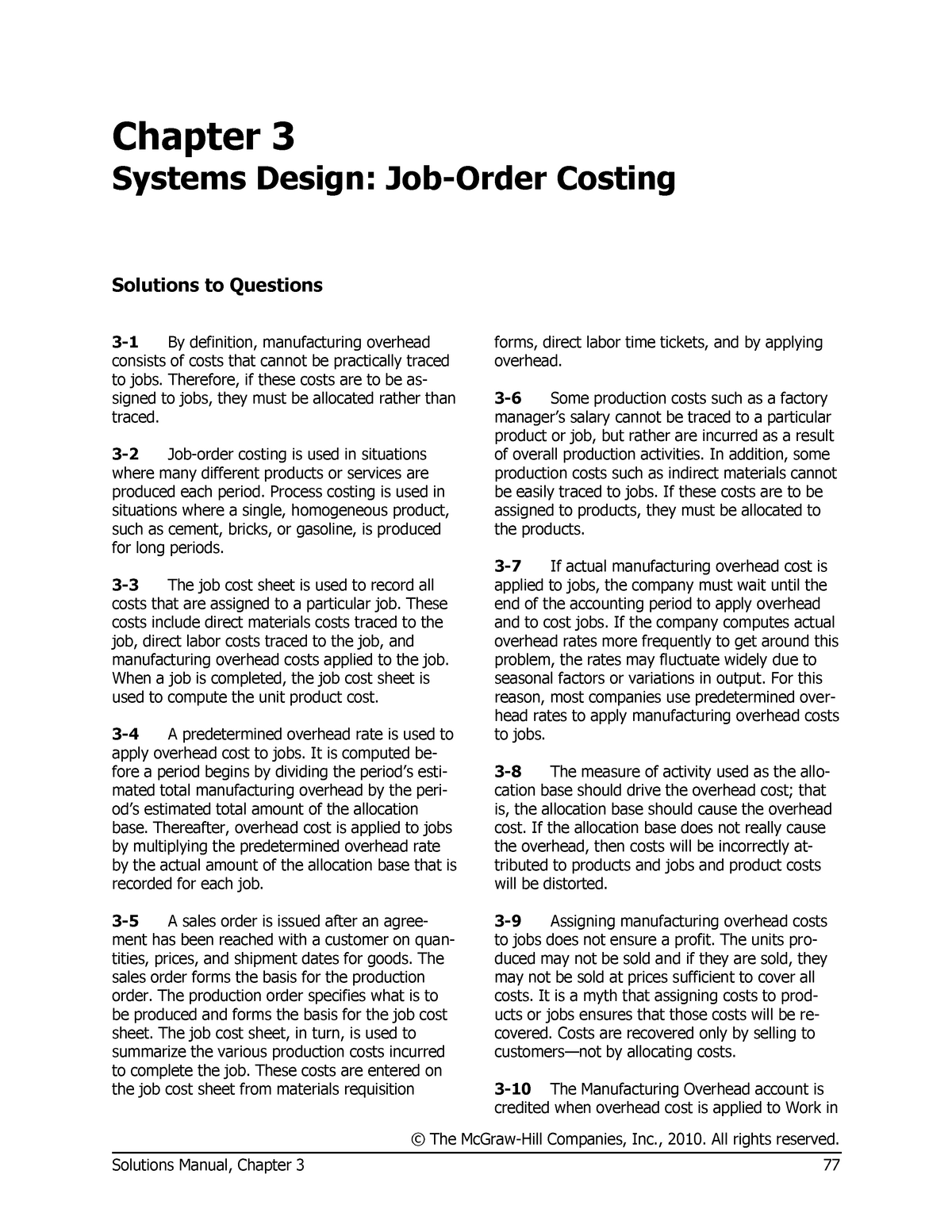

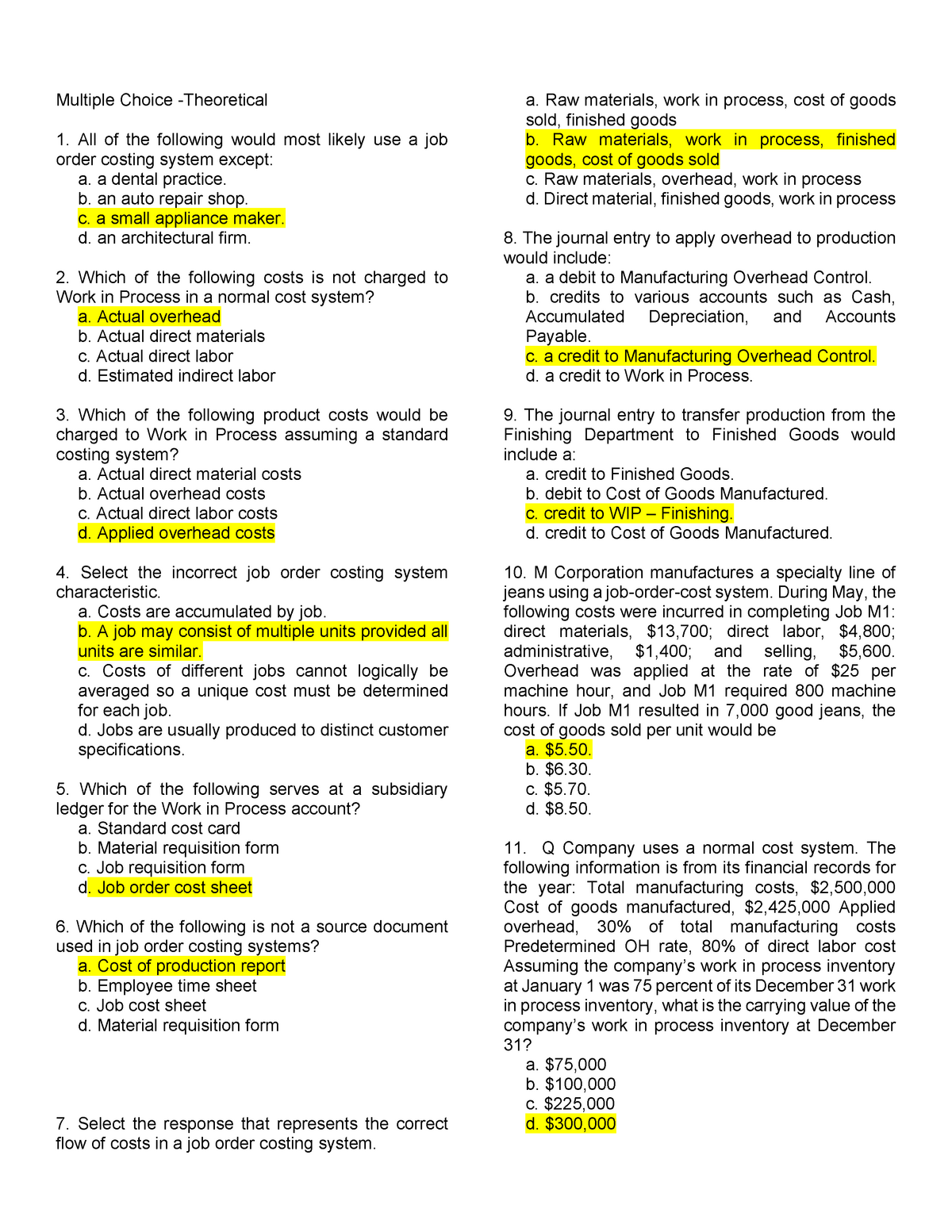

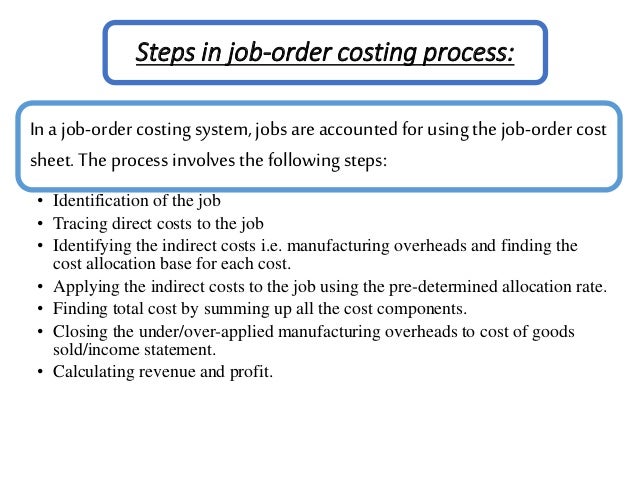

There are three types of process costing which can be used in different situations. Just as a company provides financial statement information to external stakeholders for decision-making they must provide costing information to internal managerial decision makers. 19 Describe and Identify the Three Major Components of Product Costs under Job Order Costing.

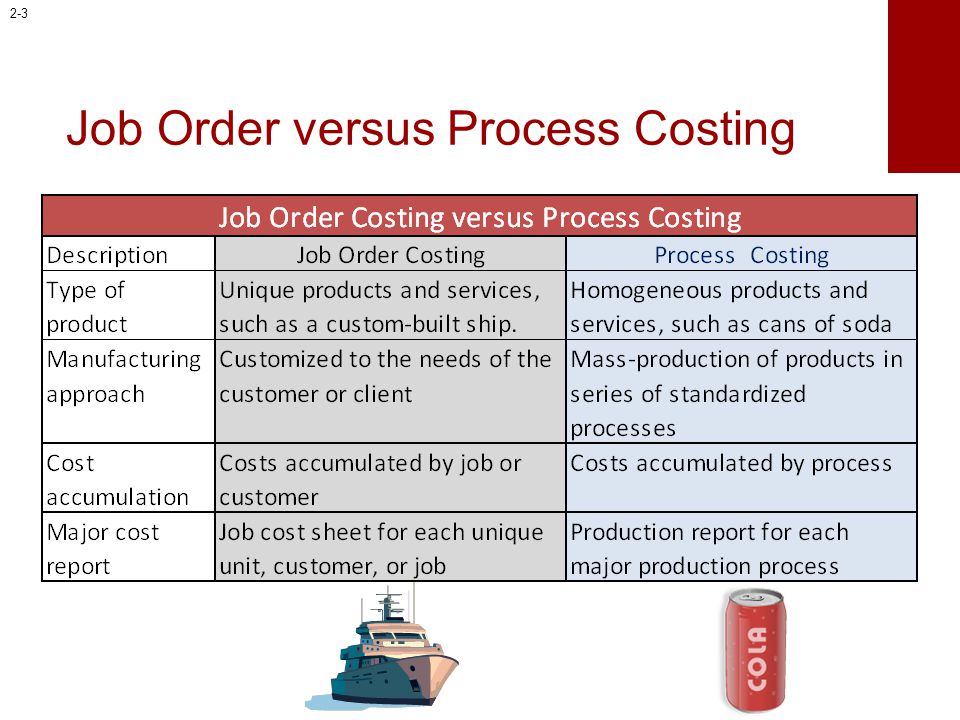

41 Distinguish between Job Order Costing and Process Costing. Study of system improvement methods and strategies.

Five inventory types with examples.

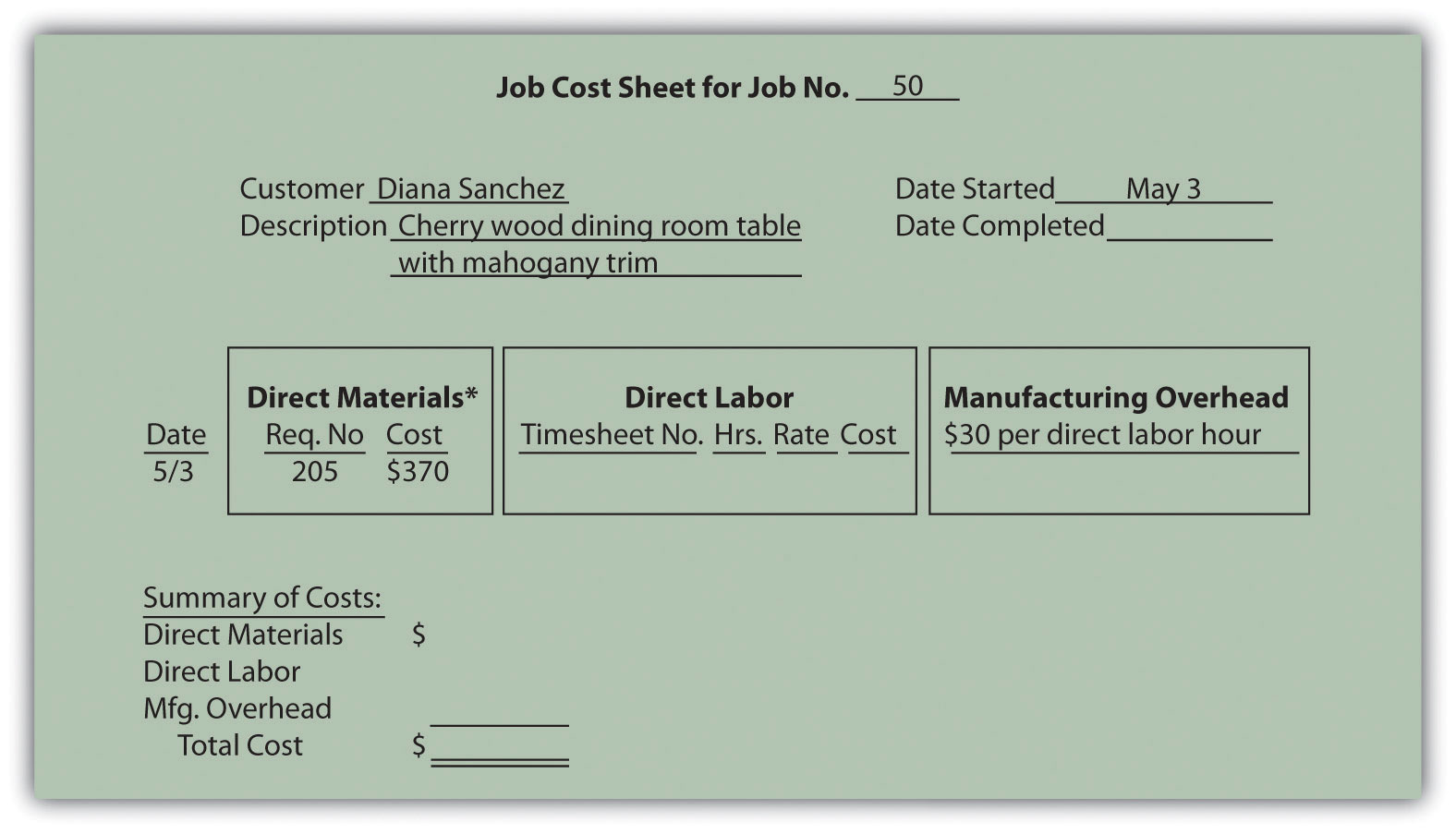

Job order costing is often a more complex system and is appropriate when the level of detail is necessary as discussed in Job Order Costing. 44 Compute a Predetermined Overhead Rate and Apply Overhead to Production. Job Costing system preferences. The information needed include. Raw materials are the items manufacturers use to make their finished products. After placing your order by submitting your assignment instructions make payments. Credit or enrollment in I E 271. Your team matters just as much as your great business idea. 43 Use the Job Order Costing Method to Trace the Flow of Product Costs through the Inventory Accounts.

Raw materials are the items manufacturers use to make their finished products. The world of manufacturing is constantly changing. Job order costing is a system of assigning the cost of production to a specific manufacturing job. The product cost is aggregate of costs that are associated with a unit of product. Here are the five most common types of manufacturing inventory. Life cycle assessment or LCA also known as life cycle analysis is a methodology for assessing environmental impacts associated with all the stages of the life cycle of a commercial product process or service. 41 Distinguish between Job Order Costing and Process Costing.

:max_bytes(150000):strip_icc()/dotdash-INV-final-Absorption-Costing-May-2021-01-bcb4092dc6044f51b926837f0a9086a6.jpg)

Post a Comment for "The Three Types Of Manufacturing Costs In A Job Order Costing System Include"